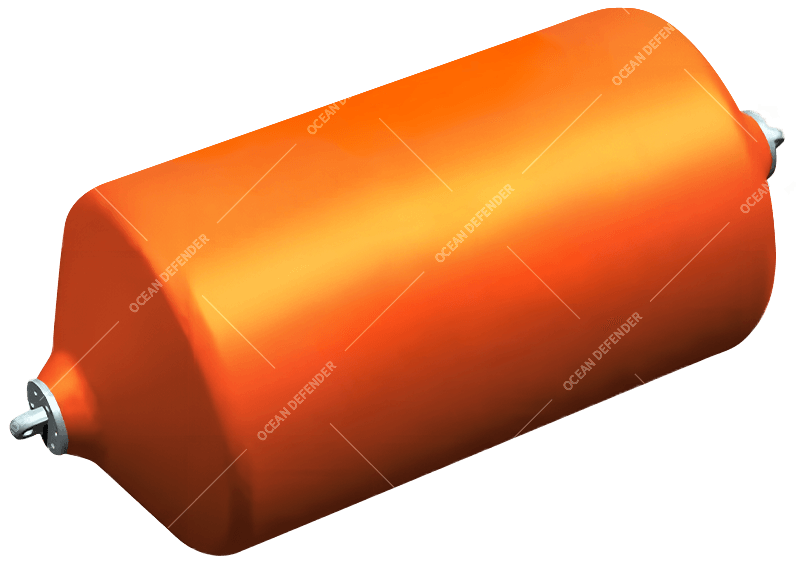

Donut Fender

Specific Type Foam Fender

Donut Fender is a specific type of foam fender which is the effective solution for simple berthing dolphins, guiding and turning structures. Due to its construction, the fender floats up and down with the fluctuating water levels and rotates when vessels berth and slide along the fender.

Donut Fender constructed 100% closed cell foam core, polyurethane skin with continuous nylon filaments. The internal casing has long-lasting, low-friction bearings which need minimal maintenance. The foam is unsinkable and cannot burst or deflate.

Donut Fener Applications

- Locks and dry dock entrances

- Corner protection

- Turning/Monopile structures

- Simple breasting dolphins

- Bridge protection

- Large tidal variations area

Donut Fender Features

- 360° rotates around a pile

- Rises and falls with water level

- Fast and easy to install

- Low shearing forces

- Low hull pressures

- Non-marking skin

- Almost maintenance free

- Custom sizes

Donut Fender Structural Design

Donut Fender can be applied for special purpose, mainly due to the fender Unique Structural Design, Superior Original Material and World-Leading Production Technology.

- 01-Heavy Duty Inner Tube

- 02-UHMW PE Pads

- 03-Closed Cell Foam Core (100%)

- 04-Nylon Filament Reinforcement Layer

- 05-Corrosion Resistance Polyurethane Skin

01 Heavy Duty Inner Tube

Galvanized heavy duty inner tube is the support and load-bearing structure. Its strength directly determines the service life of the fenders. Inner tube can be customized by requirements.

02 UHMW PE Pads

UHMW PE Pads (Ultra High Molecular Weight Polyethylene Pads) which has long-lasting, low-friction with minimal maintenance.

03 Closed Cell Foam Core (100%)

Due to the molecular structure of Closed Cell (Isolation of Gas), so the foam core can maintain excellent elasticity which is the basis of foam fender performance. Donut Fender utilizing only cross-linked, closed cell polyethylene.

04 Nylon Filament Reinforcement Layer

Donut Fender is constructed Continuous Tough and Thick Nylon Filament Reinforcement in Polyurethane skin which provides superior strength.

05 Corrosion Resistance Polyurethane Skin

High performance Polyurethane skin: Anti-acid, Alkali and salt corrosion, Anti-UV resistant, Non-marking which makes the Donut Fender skin extremely durable to all types of weather, forces and marine conditions.

Donut Fender Performance Spec.

Do you have any question?

Foam Fender Qualifications and Certifications

SHANDONG NANHAI AIRBAG ENGINEERING CO.,LTD. established since 2006, which is the international leading manufacturer in marine fender and marine airbag production. NANHAI is also the China leading brand in offshore buoyancy engineering industry. Company focuses on various areas including port infrastructure, berthing and mooring, offshore floating structure R&D, design and technology application ( offshore wind power, marine aquaculture, oil and gas, bridge protection, etc. ) After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

ISO 9001:2015

ISO 14001:2015

ISO 45001:2018

BV Certifications

Would you like to know more about Ocean Defender?

Contact us now!

NANHAI Other Marine Industrial Forms

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Berthing, Mooring, Ship to Ship, Ocean Wind Power, Deep-Sea Farming, Buoyancy and Salvage, Bridge Blocking, Ship Launching, Dock Caisson Moving etc.